10th September 2021

10th September 2021

With regular and unstable extreme weather conditions impacting the planet, ports are at the forefront of extreme heat and cold, high winds and rainstorms.

Autonomous trucks can operate around the clock 24/7 under extreme weather conditions. It takes approximately two hours to fully recharge an autonomous truck with expected 20 hours of operational time under normal operating conditions.

The vehicle is purposely designed to handle a maximum of 80 tons of loading that caters for almost all practical scenarios.

Autonomous trucks are powered by an electric motor and therefore environmentally friendly. Producing no emissions and reducing noise pollutions on the waterfront, makes them beneficial to the environment and the health of the yard personnel.

As part of the Group’s Environmental Strategy, emissions reduction is an important initiative. Migrating from conventional diesel trucks to electric trucks with autonomous driving features would deliver the promise of a green port and the preferred partner for a sustainable supply chain.

With the huge impact of the COVID-19 pandemic, many normal business practices are affected. As a result, container yard personnel have not always been able to report for duty, due to illness or local quarantine restrictions which resulted in many ports having to deploy extra resources at short notice.

In these scenarios autonomous trucks can play an important role in delivering an unlimited level of support, as they can operate for days at a time, offering respite to any backlogs of containers and ensuring the continuity of regular services to the port.

The autonomous truck technology has brought many possibilities to port operations and is designed to fit many operating configurations including manual, semiautomatic and remote-control terminals.

It adds flexibility across all types of terminals, such as the greenfield and brownfield sites, where it can meet the requirements of operating space, IT systems and local acceptance. This technology will also be very suitable for new terminals and terminal expansion projects as the terminal design layout and infrastructure can be autonomous truck specific.

Another positive outcome of adopting autonomous truck technology is the cost savings of repairs and maintenance. When comparing an autonomous truck to a diesel truck, it is more cost-effective as diesel engines are more costly to maintain and repair than electric vehicles.

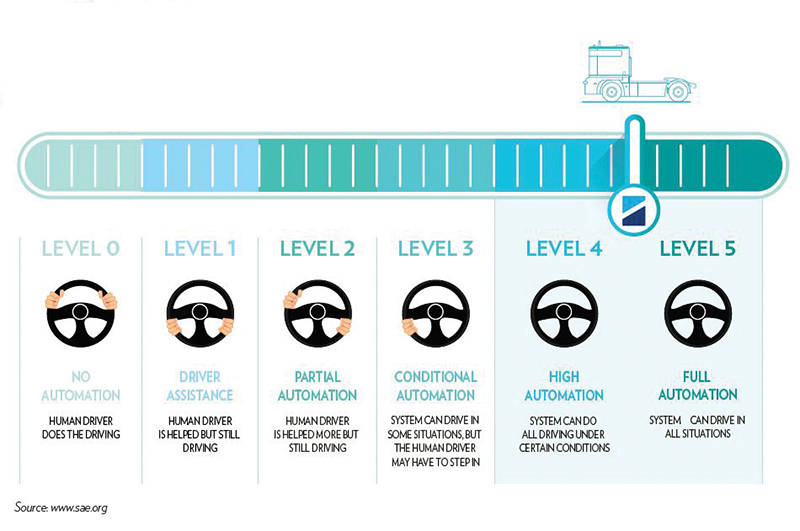

The Society of Automotive Engineers (SAE) has defined six levels of driving automation ranging from 0 (manual) to 5 (full automation).

Terminal D’s autonomous truck has attained in between level 4 to level 5 of automation, capable of doing all driving tasks under specific circumstances and within a certain area.