06th December 2019

06th December 2019

As the global supply chain faces new risks such as extreme weather, escalating cargo crime, environmental damage and political turmoil, there are calls for logistics professionals to take a new approach to manage this volatility.

Risk management expert Omera Khan, Executive Strategy Advisor for Risk Intelligence and Professor of Supply Chain Management at Royal Holloway, University of London said: “Raging trade wars are causing price hikes, which are disrupting global supply chains. There are also changes in demographics due to the rise of urbanisation and the depletion of our green and rural areas that could have a ripple effect for certain supply chains that rely on natural resources.”

Consumer awareness of the ecological impact of the products they consume is also forcing logistics companies to rethink their strategic approach to their supply chains.

According to Khan, there is a need for a new way of thinking to mitigate risk and to look at broader collaborative solutions. Logistics managers in the future will need to respond flexibly and be adaptable to shifts in the supply chain.

Niels Worsoe, Risk Intelligence’s LandRisk project manager says that in the language of risk management and risk mitigation, a ‘threat’ is very different from a ‘risk’—and it is vital to understand the difference between the two.

“A ‘threat’ becomes a ‘risk’ when a company has understood its own vulnerabilities, assessed those risks and mitigates them—better locks, choosing a different route, mandating the use of secure parking, and so on. The better you know your enemy, the better you can mitigate the threats it poses. It’s about ‘hardening’ your supply chains and shipments and making them more resilient to the threats that are out there. And the more you know about where those threats are, and the modus operandi of the perpetrators, the better you can do this,” said Worsoe.

Moreover, he added, it is important to understand that greater threat awareness and supply chain ‘hardening’ are investments, rather than just costs. Put another way, he stresses, they have a definite Return on Investment.

“We need a mindset shift as supply chain management is no longer about getting product from A to B. Supply chain is about collaboration, flexibility and adaptability. There is a need to get back to the drawing board and recognise that the new normal is doing business in an environment that is volatile and turbulent.” he added.

“We require skilled people that can be creative, think ‘out-of-the-box’, work across functions and have mixed skills and competencies,” said Khan.

“Inertia, complacency to embrace change and risk are the biggest failures for many organisations,” she added.

Training will play a key role in managing supply chain risks, according to Khan, with modular courses specifically focused on minimising and managing risk and apprenticeships to train the supply chain managers of the future.

Cargo crime figures continue to grow at an alarming rate, and Khan says that transport-related theft is increasing in sophistication.

“Partnering with risk intelligence providers should be considered as part of an organisation’s strategic risk management approach. These strategic risk partners can help provide on-time alerts and rerouting and advice on safe parking spots amongst a myriad of many more optimal solutions.”

ln the real world of cargo crime in the supply chain, statistics can make for some chilling reading, with soaring land-based raids on trucks and warehouses.

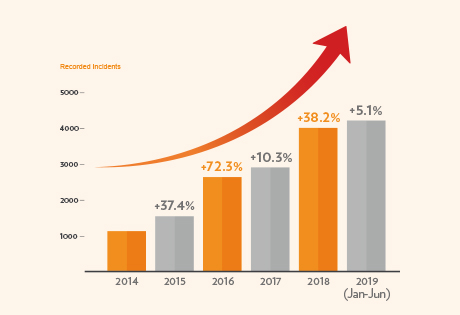

For the last five years, Transported Asset Protection Association’s (TAPA) Incident Information Service (IIS) reported that cargo crime in Europe, the Middle East and Africa (EMEA) region has seen record year-on-year growth from 2015-2019 inclusive.

For the first six months of this year the number of incidents reported to TAPA’s IIS have broken new records, according to an article published on TAPA’s official website.

The 4,187 crimes published in the TAPA IIS EMEA Reports for the first six months of 2019 surpasses the 2018 whole year by 5.1 per cent and shows a total value for incidents with financial data of more than €55 million or an average of €305,605 per day.

Behind these alarming numbers, however, sits some very positive news; the growing trust and intelligence sharing between national law enforcement agencies in EMEA and TAPA, which is providing new data base and vital information for security professionals trying to protect their supply chains across the region or, in other words, significantly reducing the likelihood of becoming a victim of cargo thieves.

A recent meeting of TAPA’s Asia Pacific membership resolved that supply chains need to react faster to embrace supply chain resilience. The members also agreed that by complying with TAPA’s security standards, it will help them be better prepared for unexpected risk events. Adhering to the standards will also help shorten response recovery times to potential disruptions and return supply chains to their original status, according to an article in TAPA’s September issue of Vigilant magazine.

The article went on to highlight the major impact cyberattacks have had on supply chains, which have exposed major gaps, which are not necessarily addressed in current supply chain security standards or may not be scalable for all stakeholders.

To combat the smuggling of counterfeit goods, which costs brands and retailers billions of dollars every year, TAPA’s relationships with global law enforcement agencies could help to significantly reduce crimes, as well as adopting TAPA’s systematic approach to managing risk.

Another suggestion was that TAPA’s IIS cargo crime data should be used in logistical planning to learn more about the modus operandi of criminals and help logistics companies prevent new incidents from occurring.

The Asia Pacific members concluded that data sharing can be achieved between collaborative partners under a MOU for the benefit of all stakeholders.

THE NEW PARKING SECURITY REQUIREMENTS STANDARD

Thorsten Neumann, Chairman of TAPA Europe, the Middle East and Africa (EMEA) said, “There is no quick fix to tackle the risks of truck drivers and cargoes face when they have to stop in unsecured locations. However, at an industry level, we have to start providing more controlled parking areas that offer improved safety and security and reduce the need for vehicles to stop in laybys, on industrial estates and at motorway service areas where statistics show they are highly vulnerable to attack. We are working hard to engage with parking place operators to highlight the commercial benefits of being TAPA-approved, and we are also encouraging our members who book parking spaces to promote the new Parking Security Requirements (PSR) standard to the parking site owners they know.”

TAPA’s new PSR and secure parking programme in EMEA now totals 4,900 sites in 10 countries and there are 55 new sites in the pipeline.