17th December 2020

17th December 2020

The inexorable rise of e-commerce triggered by a massive increase in on-line shopping during the last five years, has been boosted by the COVID-19 pandemic, as housebound consumers tend to buy daily necessities via their home computers.

This phenomenon has had a knock-on effect as brand named e-commerce companies are expanding their sourcing operations to a broader range of global suppliers in order to keep pace with evolving consumer demand for products. Casting the sourcing net wider also increases supplier competition and ensures low prices for the consumer.

As supply chains expand to incorporate new suppliers, the risks of supply chain disruption increase exponentially, so a smart inventory management strategy is becoming essential to ensure a flexible response, maintain optimal stock levels and develop cross border sales opportunities. In the past, the industrywide emphasis was on just-in-time delivery, which is extremely efficient and productive, but it also means there is very little buffer stock when there are disruptions in the supply chain.

The COVID-19 pandemic has had a major impact on world trade and provided numerous lessons for the shipping and logistics sectors. One of the key developments is demand for increased visibility into inventory levels, to avoid being left with warehouses full of expired or unsold stock.

One of the risks that sellers have while working with new suppliers is the uncertainty of whether they can deliver on-time, particularly if they use an inefficient inventory management system which ultimately impacts the bottom line of the seller. Sourcing the right products with the right suppliers, while implementing operational efficiencies, will become more crucial than ever to sustaining sales and growth in this new retail environment.

The coronavirus has also shifted consumer buying behaviour to focus on health and medical products, food and groceries according to Peter van Merode, Vice President 3PL Strategy at Blue Yonder reported in Logistics Management magazine.

High street stores are struggling with changing consumer buying behaviour and increasing their on-line capabilities is essential for their survival. In order to maintain viability and retain customers, many are already investing in intelligent inventory management capabilities at the core of their supply chains.

To cope with high demand, logistics companies must adapt to the new reality of increased volumes for groceries, pharmaceuticals and healthcare products. This will require more investment in temperature-controlled warehouses and an effective cold chain strategy both locally and for cross border shipments.

Inventory management will be vital to reducing the impact of COVID-19 on the supply chain, by supporting demand management and providing fulfilment strategies to many industries.

Looking at empty shelves in many of the world’s supermarkets is not just a symptom of panic buying but also of the fact that we have become used to lean supply chains, according to Tiago Martins of HLB Consulting Brasil.

“The culture of operating without stock in the ‘just-in-time’ system contributes to a shortage of products on the shelves and fluctuations in the supply chain are enhanced by ‘phenomena’ such as the COVID-19 pandemic,” said Martins.

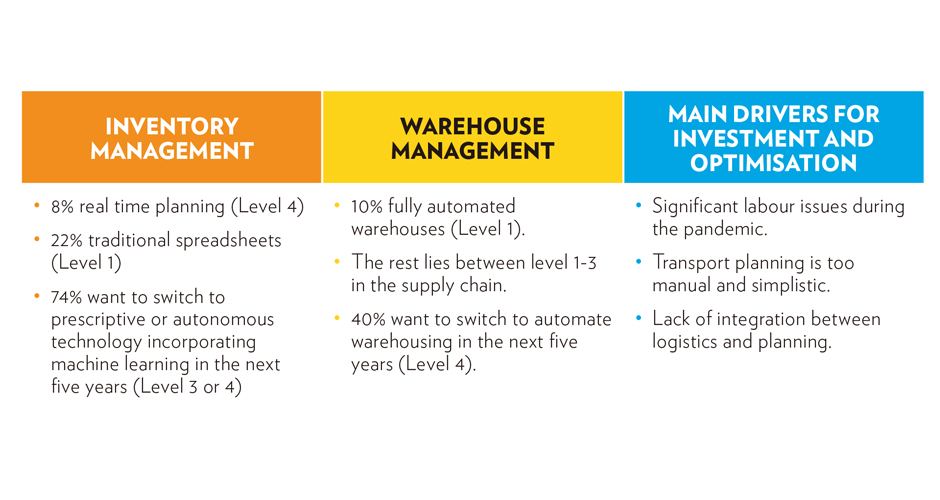

In a major study held by Blue Yonder and the University of Warwick (between March and April in 2020) which surveyed 104 retailers and answers laid bare the scale of the transition needed by traditional retailers to meet consumer demand during the pandemic.

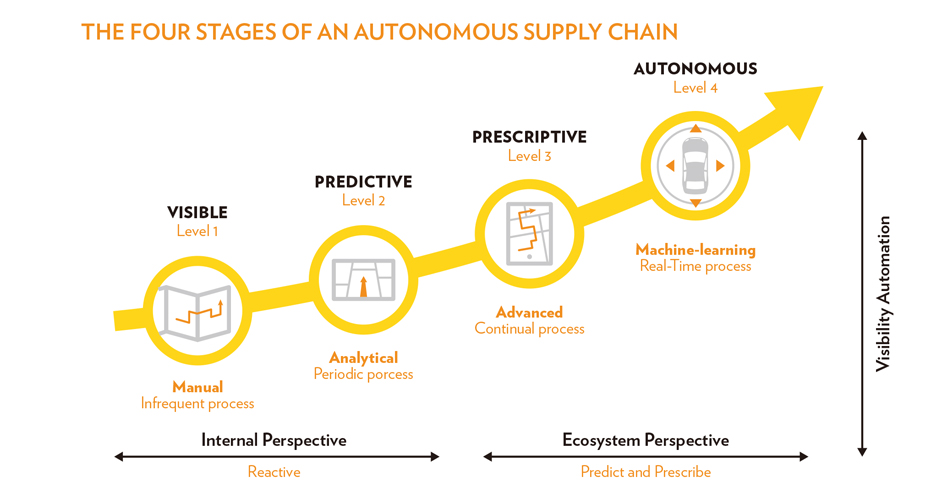

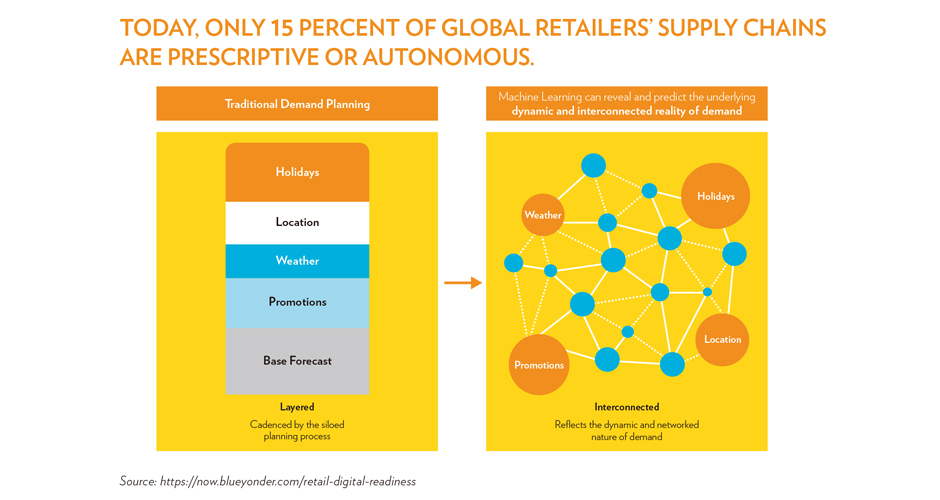

The major lesson learned by retailers during the pandemic is to be more flexible in response to fast moving consumer demand. According to the survey, major investment in the future will be in demand forecasting, visibility and automation, in order to meet the tectonic changes in the retail sector.

At the heart of this transition will be inventory management, with AI and Machine Learning supporting demand planning and optimising stock levels, on-time deliveries and replenishment.

From the major supply chain disruption caused by the pandemic, there is an opportunity for logistics operators and warehouse management companies to attract new retail customers, looking to transition from the High Street to e-commerce.

The inventory management sector will be able to leverage its expertise, knowledge and data mining to optimise solutions for the new generation of retailers looking to break into e-commerce.

For those companies in the retail supply chain who have not yet digitised their operations, the pandemic has acted as wake-up call. Increasingly, consumer demand for products driven by on-line purchases can only be met by an interconnected digital supply chain. Warehouse and inventory management companies who remain in the analogue world need to reboot their operations and reap the benefits. Otherwise they are likely to go the same way as the fax machine.