22nd December 2022

22nd December 2022

Hydrogen is the first element of the periodic table as its atomic number is one, which means it has only one electron in its atom and thus only one electron is present in its outermost shell. The placement of elements in the periodic table is based on their electronic configuration.

It is composed of a single proton and a single electron. Liquid hydrogen is used in the study of superconductors and makes an excellent rocket fuel when combined with liquid oxygen. Numerous compounds are formed by hydrogen combined with other elements.

Hydrogen is also perceived as the magic bullet that will reduce carbon dioxide (CO2) and Greenhouse Gas Emissions. It is the most abundant gas in the universe and the cleanest energy source on the planet.

Forecasts are that hydrogen consumption will represent 24 percent of the global energy sector by 2050, with an investment of US$2.5 trillion.

These compelling facts have led to a race both on land and at sea to harness the potential of hydrogen and provide the sustainable fuel that we need to slow the pace of global warming.

We have all experienced the consequences of climate change in recent years, with droughts, flooding, crop failures and extremely high temperatures all over the planet.

SO WHY IS HYDROGEN SO IMPORTANT AND WHAT ARE ITS PROPERTIES AS A GAS AND AN ENERGY SOURCE?

If hydrogen sounds too good to be true, there are certainly some caveats that need to be considered, including the fact that hydrogen in the form of gas is also the most explosive substance in the universe.

Other challenges that need to be resolved are the safest, greenest and most cost-effective way of harvesting and transporting the gas.

The level of hype around hydrogen is driven by the thriving clean energy industry, racing to find the replacement for fossil fuels and the emissions that continue to increase CO2 levels in the atmosphere leading to global warming.

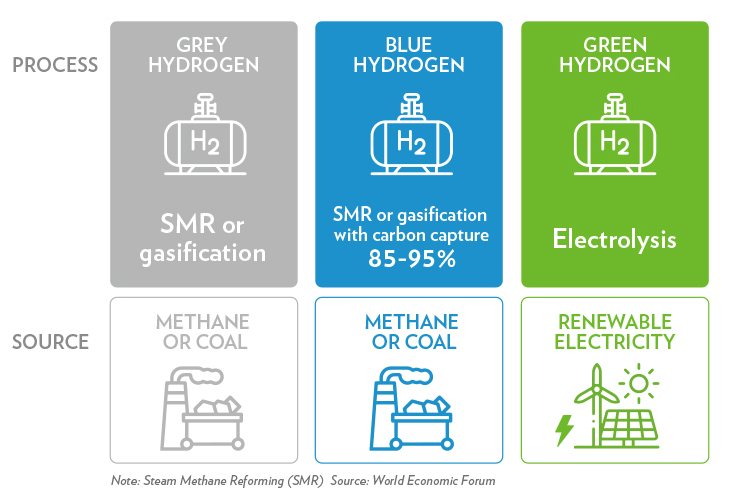

There are a few types of hydrogen that are classified by the way the gas is produced, namely Grey, Blue, and Green. Today, hydrogen fuel can be produced through several methods. The most common methods are natural gas reforming (a thermal process), and electrolysis. Other methods include solar-driven and biological processes. Grey hydrogen is produced by burning natural gas at high temperatures and if the carbon is removed or captured then the result is Blue hydrogen.

Green hydrogen is produced through the electrolysis of water or by using renewable energy sources such as solar cell, hydropower, wind energy and nuclear to avoid any emissions during the production stages.

As the preferable option, green hydrogen is in demand but is also sensitive to price hikes in electricity needed in the electrolysis process along with water.

The cost of hydrogen from US electrolysers shot up to $16.80/kg in July this year (2022) as a result of energy price hikes during a heatwave between 6 -12 July 2022, according to data from S&P Global Commodity Insights.

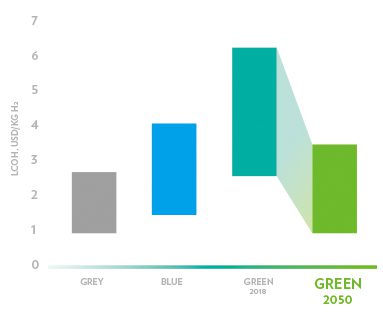

Despite the efficiency of green hydrogen compared to other types, its price remains a major obstacle in the promotion and marketing, which is estimated at 3.5 Euro/kg, compared to 1.5 Euro/kg for blue hydrogen.

Liquid hydrogen is also being used for submarines and other naval vessels, but the gas only liquefies at extreme low temperature using cryogenic tanks, again proving to be very expensive to produce, store and transport.

Renewable hydrogen production costs could fall faster than estimated, if scaled up with the right long term regulatory framework and public support, along with a continued decline in renewable costs, and a rapid scale-up of value chains for electrolysis and carbon management. Estimates are that hydrogen costs will fall by about 50 percent to make the gas competitive with low-cost alternatives and even fossil fuels, according to the Hydrogen Council.

The applications for hydrogen now include hydrogen boilers, cars, short-sea ship operations and energy intensive industries such as steel production.

Qingdao Port has built a hydrogen refuelling station to supply clean energy for its operations.

The station project has two phases and is designed for a daily hydrogen supply capacity of 1,000 kilograms, which can serve 50 hydrogen fuel cell vehicles every day. The first phase of the project occupies an area of 4,000 square metres, half of the total designed capacity.

Qingdao Port started three years ago to supply hydrogen energy to container trucks by using relay-tank trucks, the filling of which takes about one hour. Today, just like any other car going to a petrol station, it only takes approximately 8-10 minutes to fill a cell vehicle with hydrogen.

Since June 2020, the port has also used hydrogen fuel cells in moving six gantry cranes at the port’s fully automated container terminal, becoming the world’s first port to do so.

Qingdao Port mentioned that leveraging both hydrogen fuel cells and lithium battery packs can reduce power consumption for a gantry crane carrying a container by 3.6 percent and save about 20 percent in purchasing costs for a single machine’s power equipment.

It is estimated to reduce emissions of 20,000 metric tons of carbon dioxide and 697 tons of sulfur dioxide annually, based on an estimated annual cargo handling capacity of 3 million twenty-foot equivalent units. (Source: China Daily Hong Kong)

Another long-term project underway to increase production capacity in Europe include Shell establishing an industrial scale 10 Megawatts (MW) electrolyser at its oil refinery in Cologne, Germany, this is the largest in the world so far. The plant will produce green fuels within a European Union funded consortium which is already setting sights on a facility of 100 MW at the site near Cologne to scale up its commercial operations.

In Rotterdam, several companies are planning to produce a combined 450 MW of power using hydrogen by 2025, rising to 110,000 MW by 2050 based on the expected demand for 20 million tons of hydrogen.

To unlock hydrogen applications, a cost-efficient transmission and distribution will be required. Long-term, a network of pipelines offers the most cost-efficient means of distribution, while in the short-to medium-term, the most competitive setup involves hydrogen production close to resource-rich regions to demand centres via trucks, trains, refuelling stations, and smaller industrial users.

Shipping can transport hydrogen over longer distances but needs to be converted to liquid hydrogen, liquid organic compounds or ammonia.

Hutchison Ports Port of Felixstowe has been chosen as an agent of economic transformation as one of the eight national freeports, Freeport East. It also has plans to become an agent of ecological change by transforming the local economy to run on emission free hydrogen.

Port of Felixstowe is examining ways to build on the steps it has already taken to eventually reach net-zero. It is working with partners, including Ryse Hydrogen, to explore the use of hydrogen powered port equipment and with Cranfield University, Sizewell C and EDF, the Port of Felixstowe is involved in one of the projects selected to receive support from the Clean Maritime Demonstration Competition.

The project involves a feasibility study into the potential for Freeport East, which includes the ports of Felixstowe and Harwich International, to become a net-zero port and a net-zero energy hub for third parties and the adjacent region.

Commenting on the project, Clemence Cheng, Chief Executive Officer at the Port of Felixstowe, said: “There is considerable use of fossil fuel in ports all over the world. Replacing hydrocarbons completely is a huge challenge. Technology replacements are in some cases becoming available but, in many cases, they are in their infancy or face other hurdles to adoption. All solutions demand very significant investment. The study will identify which solutions give the best viable outcome regarding speed and efficacy towards net zero.”

In addition to decarbonising the port’s own operations, the study will also consider how Freeport East can play a role in helping to reduce or eliminate carbon from associated and adjacent businesses.

To learn more please read SHIP2SHORE magazine #35.

With the dawn of the green hydrogen economy, there is demand to make zero carbon fuels from water, and produce those fuels with a true-zero emission energy source. Advanced nuclear floating production platforms are being designed and tested to produce green hydrogen as well as ammonia and methanol as fuels for shipping and heavy industry.

Hydrogen electrolysers can be installed on board the floating platforms and the reactors can also power the desalination process, creating the fresh water needed for electrolysis. With a life span of 30 years, the small reactors are modular in design, emission free and highly fuel efficient.

By deploying advanced reactors offshore, the seawater acts as a heat-sink, and removes the complex site preparations including pressurised water containment structures needed on the land.

The Molten Chloride Fast Reactors, is a design with the fuel dissolved in a fluoride salt coolant, are currently being developed in the US at the Idaho National Laboratory, by a consortium that includes Bill Gate’s Terrapower, UK-based Core Power, Southern Company and French nuclear company Orano.

China and South Korea are also developing small modular atomic reactors to be deployed for energy hungry industries such as refineries, steel, fertiliser production and mining.

WHAT IS GREEN TAXATION?

Environmental or green taxes include taxes on energy, transport, pollution and resources. Energy taxes are taxes on energy products and electricity used for transport, such as petrol and diesel, and for other purposes, such as fuel oils, natural gas, coal and electricity used in heating.

As part of a broader policy mix, green taxation initiatives at both European Union (EU) and Member State level can help us to reach environmental policy goals by encouraging a switch to cleaner energy, more sustainable industry and greener habits. By setting a price for social costs, altering decision-making and incentivising behavioural changes by companies and people, this action can help mitigate resource waste and to preserve the environment.

Hydrogen has the properties needed to provide affordable, cost effective and clean energy to support the drive to lower carbon emissions and slow the rate of global warming.

Hydrogen is abundant and versatile and the technical capability to harvest this amazing resource already exists. The gas can be used to produce, store or move energy in different forms and it’s only by product is water.

This contrasts with fossil fuels, which are responsible for increasing greenhouse gas and carbon emissions.

One of the major successes of COP 26 (United Nations Climate Change Conference) held in Glasgow in 2021 was the agreement “to revisit and strengthen the 2030 targets set by the Paris Agreement in their nationally determined contributions…by the end of 2022”.

The aim of the Paris Agreement set in 2015, is to limit global warming to below 2 degrees Celsius preferably below 1.5 degrees Celsius.

In June 2021, the International Maritime Organization (IMO) adopted short-term measures to reduce the carbon intensity of all ships by 40 percent by 2030, compared to 2008. In addition, the IMO made a commitment to cut annual greenhouse gas emissions from international shipping by at least half by 2050, compared with their level in 2008, and work towards phasing out GHG emissions from shipping entirely as soon as possible in this century.

Green fuels are a major part of the IMO’s strategy to transform shipping’s reliance on fossil fuel burning ships and hydrogen is one of the energy sources leading the race to enable that change.

WHEN THE WIND DOESN’T BLOW AND THE SUN DOESN’T SHINE

One of the main challenges facing renewable energy production from using wind power and solar energy is that it is intermittent, as the wind does not always blow and the sun does not always shine.

That is why the hybrid solutions of using LNG as an energy source to produce hydrogen is being considered in the interim to complement the use of wind and solar which would at least mean production would be uninterrupted on still and sunless days.

LNG also produces less CO2 than oil and coal so there would be an incremental reduction in overall emissions, but only as an interim measure until renewable energy capacity was sufficient to meet increasing demand for hydrogen.

There will be a rapid scale up of hydrogen, but the challenge still exists that in order to produce green hydrogen there needs to be a sustainable renewable energy source such as wind, solar or nuclear.

The volume of hydrogen required to replace fossil fuels used in shipping is enormous, given the lower calorific value of the gas when compared to oil. It will take many years to scale up the hydrogen industry to meet demand both on land, sea and household.

The investment required in infrastructure and technology to transform the shipping industry to green energy will run into the trillions of dollars, but already we see ambitious developments in China and Europe that will provide a platform for future growth.

Hydrogen is just one part of the drive to create a more sustainable shipping industry and help to reduce emissions globally, other renewables such as wind, solar and nuclear will also be key to achieving the ambitious emission reduction targets.