29th April 2020

29th April 2020

Traditional supply chains have been developed in a one-way pattern of production and consumption, which despite being an engine for economic growth, is also an unsustainable model as it depletes resources, according to a study about the ‘Reverse Logistics Maturity Model’ produced by DHL, Cranfield University and the Ellen MacArthur Foundation.

The study is focused on the development of a circular economy and the need to rethink materials and energy use to reduce consumption of raw materials, such as renewable and reusable products.

For many years once a product was delivered to the consignee, that was the end of the process for logistics services providers and shippers. Now with the advent of on-line shopping, consumers are driving growth in reverse logistics. Today, there is an expectation from shoppers that a product which is delivered in the wrong size or colour will be returned free of charge.

On the industrial side of logistics, the aerospace and automotive sector has long been a leader in reverse logistics, with components being returned because they are the wrong size, shape, material or have been damaged during transit. Mechanical parts in these two sectors are often customised with individual serial numbers to ensure each product is authentic, backed by a certification process to reduce the risk of fake parts entering the supply chain.

The consumer electronics industry which includes mobile phones and computers also has a robust returns sector, although many of the products are returned to local depots or customer service facilities.

Each of the business verticals has specialist suppliers who understands the complexities of each sectors supply chain. One overriding factor is to develop a more sustainable reverse logistics supply chain with improved access to data from consumers highlighting the reasons why products are returned and how often, this can make a significant reduction in industrial waste, as products can be reused, recycled or resold to minimise loss.

Reverse logistics will play a major role in developing the circular model, transporting end of life goods to be reused and recycled and as important, managing the flow of data to enable optimal reverse supply chains, according to the Reverse Logistics Maturity Model report.

“Logistics not only the collection and transport of materials and products but value-added activities such as testing, sorting, refurbishing, recycling and redistribution,” according to the report.

Potentially a massive industry is emerging and one that ticks all of the boxes in terms of sustainability and providing a big opportunity for logistics companies, particularly those with an existing global infrastructure, to develop a new line of business utilising existing assets and expertise.

The volume of cross-border returns has increased exponentially due to globalisation, with products typically manufactured in China and sold in Europe and the United States (US). The level of complexity in returning products is high as it includes customs compliance as well as health and environmental laws and regulations.

Building a digital returns platform for shippers, logistics services providers and customers is time consuming and costly, so most companies opt to outsource physical collections to third-party logistics companies.

In the fashion industry, such as footwear and sportswear sectors, there has been a lot of waste in recent years as returned goods were not being sent back in an efficient and cost-effective way. Fashion brands did not know the reason why goods were being returned by consumers as they did not have the data.

Two experienced reverse logistics professionals in the United Kingdom (UK), Graham Best and Phil Smith, Co-Founder of ReBOUND, saw the opportunity to provide an integrated platform focused on online shopping, connecting consumers, retailers, delivery and logistics companies.

The company helps many of the UK’s leading retail brands as their customers, who manage their entire returns business through their integrated reverse logistics platform.

“Consumers now expect a free returns policy from online retailers and it makes sense to integrate all of the reverse logistics through a single platform, enabling transparency throughout the whole process and providing data that can be used to improve efficiency and reduce costs,” said Graham Best, CEO and Co-Founder of ReBOUND.

If a retailer’s returns policy is poorly reviewed, then the consumer will not trust the retailer and they will shop elsewhere. In contrast a good returns service attracts business from larger global markets, based solely on the trusted returns policy. Free returns are now used as a marketing pitch and provide competitive advantage to many leading retailers.

“Returns are no longer an afterthought for retailers, who are now factoring returns into their digital strategy to ensure they are not a barrier to cross-border trade. The US and Europe are typically high-volume lanes for UK brands, but more recently key online players are also ramping up sales in Asia and Russia,” said Best.

Zappos, an online retailer of shoes and apparel, built its success on the promise of free and easy returns. The company actually encourages customers to order two sizes of shoes to make sure they end up with one pair that fits. Zappos’ use of logistics as a competitive service advantage is one reason 75 per cent of the retailer’s shoppers are repeat customers. While this policy drives up return volumes and shipping costs, it reduces customers’ hesitancy to place an order and results in more sales overall. (Source: 6 Things You Can Do To Make Returns a Competitive Advantage by Fortna)

Amazon centralises returns in a single facility for efficiency. The Lexington, Kentucky facility is designed to handle both inbound returns and outbound disposition of returned inventory. Amazon makes it easy for customers by providing a pre-paid shipping label so packages can be dropped off or scheduled for pick-up by UPS. For prime-eligible items, the company credits the customer’s account within 24-48 hours of initiating the return; in many cases before the customer has even shipped it, to encourage the order of replacement or additional items.

Hermes fulfilment is the largest fully automated reverse logistics warehouse in the world. Rather than continue to manually sort returns in its picking warehouse, Hermes looked to automation technology to increase efficiency and accuracy.

The automatic returns management system has a storage capacity of 1 million items in approximately 176,000 storage locations. Most products remain in the system for only a few hours. Utilising up to 30 workstations on two levels, up to 15,000 items per hour are processed during peak times.

The use of automation at Hermes has enabled the company to process returns faster with greater flexibility. They’ve also been able to improve quality with greater accuracy and make better use of the space in the facility.

SIX THINGS YOU CAN DO TO MAKE RETURNS A COMPETITIVE ADVANTAGE

(Source: Fortna)

In the UK alone where returns rates average 30 per cent for the fashion sector, ReBOUND estimates that the impact of clothing returns over peak would have amounted to US$2.6 billion in 2019. The returns specialists also estimate that global returns across all product verticals would have cost UK retailers approximately US$90 billion in 2018.

According to the US based National Retail Federation, if returns were a corporation, they would rank number 3 on the Fortune 500 list.

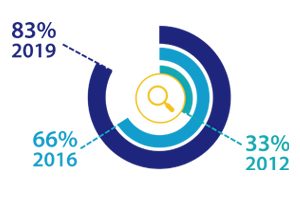

More shoppers than ever are looking at the return policy before buying.

RETURNS POLICY CONSUMER DEMAND INDEX

Returns behaviour varies across verticals – for instance footwear experiences higher returns rates at around 10 per cent higher than other clothings and ladies evening wear can be double the norm for daywear, according to ReBOUND’s statistics. The sports leisure wear sector is also growing very quickly following a similar profile to fashion.

Boom regions for reverse logistics are North America, Europe, Russia, Hong Kong and Australia; but there are also positive signs in South America, the Middle East, South East Asia and Mainland China are all moving up, according to Best.

FIVE REASONS ORGANISATIONS SHOULD IMPLEMENT THEIR OWN REVERSE LOGISTICS STRATEGIES:

(Source: Paul Hinz, Adaptalift Group website, Logistics Blog)