10th September 2021

10th September 2021

The success of implementing autonomous truck to Terminal D is reliant on its advanced technology and the re-creation of a new terminal operating ecosystem. It provides a perfect platform for the next generation of ports with safety at the heart to future developments.

Being able to make safe decisions while navigating a busy terminal is vital to any port operation. The onboard AI and the advanced sensors installed in the autonomous truck allow it to make safer decisions on the routes, including changes in direction and vehicle speed.

Like manned conventional trucks, the flexibility of last-minute change in the loading sequence is crucial to terminal efficiency. Having received instruction from the quayside checker, the autonomous truck can execute a newly assigned task to reduce downtime during idle mode in queue and adds more flexibility to the planned loading sequence.

The autonomous truck also has a powerful processing platform onboard which enables it to operate in a real time environment with data collected from the sensors.

Having rigorous end-to-end machine learning, the autonomous truck will be able to learn a set of driving skills, such as self-organising intelligence, lane-keeping, overtaking, obstacle avoidance and intersection turning in structured and unstructured roads.

The autonomous truck has the advantage of 360-degree wide perspective providing real-time, all-round ‘vision’ enabling it to instantaneously ‘see’ everything in its vicinity to achieve safety and accuracy during navigation. With the support of Extreme Precise Position (EPP) system, it can achieve positioning accuracy of 2 cm and a steering angle within only 0.5 degrees. It can achieve a one-time position success rate of over 97 percent.

Unlike conventional trucks with mechanical control, the autonomous truck relies on electronic control signals, which allow for quick response time and enable safer and smoother manoeuvres. This is convenient and suitable for autonomous driving in enclosed areas, such as ports and terminals.

Safety is of primary importance to all technological developments and especially considered when introducing new technology into terminal operations around the world.

The autonomous truck has built-in safety features which allow the vehicle to navigate effectively and safely in harmony with the conventional trucks. An emergency safety stop function is embedded into each truck. For example, should a vehicle bypass yard traffic rules; unexpected human activity occurs or when unavoidable obstacles or aggressive driving are present, the safety stop function will be activated and engaged to ensure optimal safety.

The maximum speed is also pre-set at 30 km/h, which is the terminal safe driving speed limit for all trucks.

To increase the safety level of staff working in yard, the project team has introduced the centralised twistlock station into its daily operation flow. Stevedores are relocated from underneath the quay crane to the backreach area, protected by the twistlock station, to ensure a safe working environment while securing or removing the twistlock cones.

The quayside checkers are now repositioned in a quay crane checker cabin on ground level to verify container conditions through HD cameras and confirm movements with nGen.

Junction management and the behaviour of an autonomous truck are critical to maintain safe and smooth traffic flow in the terminal. The predefined landmarks and traffic signs improve navigation and add clarity to terminal users, especially at road junctions and complex traffic conditions.

A new set of traffic policies have been introduced to external truck drivers and terminal staff on autonomous truck awareness. Multiple sessions of training programme have been held and targeted to reach over 30,000 truck drivers in the Laem Chabang port area to enforce terminal safety while working in mixed traffic mode at Terminal D.

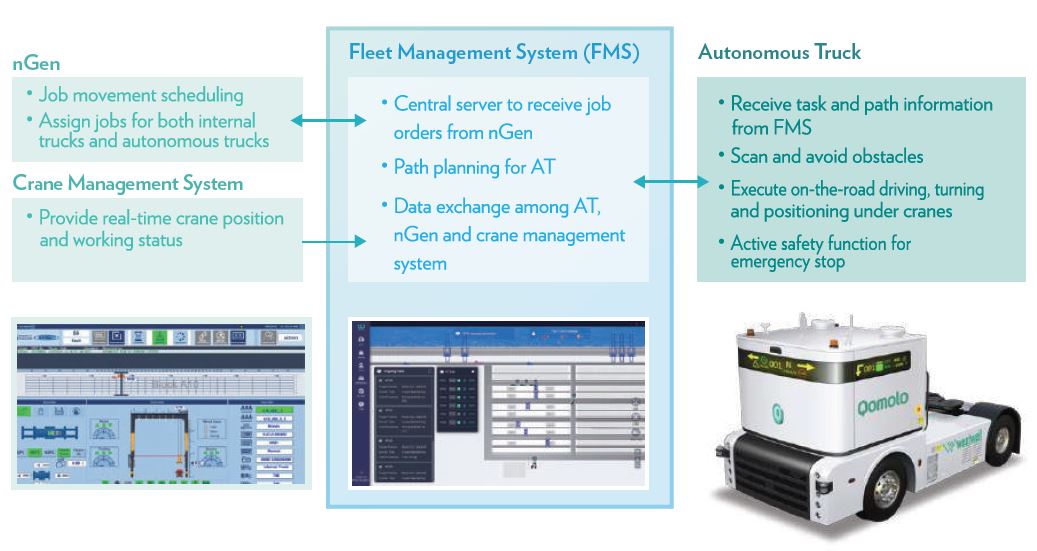

Fleet Management System (FMS) coordinates and plans the routing for each autonomous truck. The FMS receives job order messages from nGen and then disseminates path planning from the autonomous truck’s current location to the destination. It interacts with nGen and other crane management systems, which helps to extend the terminal’s capability in becoming even more automated.

By defining safety procedures and extensive education, the Group’s Global Minimum Safety Standards (GMSS) Clause 12.11 requires that drivers of internal and external tractors to stay inside the vehicle except in emergency in order to realise a safe working environment in the yard.

To ensure yard personnel are not at risk, an intelligent yard surveillance system add-on software has been integrated to the current high-definition CCTV system to detect any human activities in restricted areas.

Any personnel that are in the vicinity of the autonomous truck during operations will trigger a warning alert. The safety team will quickly respond to maintain smooth yard traffic flow and personnel safety.