29th April 2020

29th April 2020

During the last 50 years, simulation technology has found its way from technical applications into the logistics sector. Driven by increased demand for high productivity, due in part to the introduction of larger container vessels, specific computer systems for simulation were developed for container terminals.

The latest strategic approach is to use digital simulation technologies for planning, developing and the installation process of a container terminal, according to Holger Schuett, Managing Director of akquinet AG port consulting GmbH.

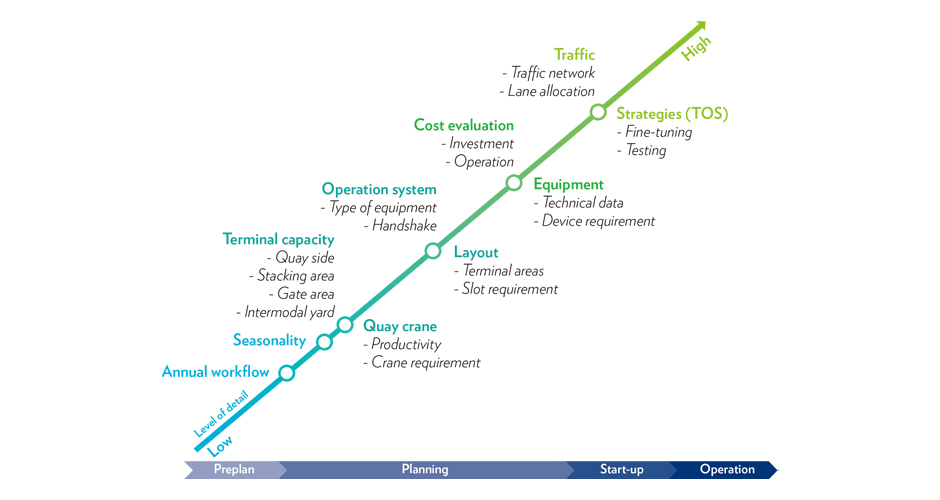

At the beginning of the process there is little information available about the planned terminal and the main task is to visualise the idea of the new terminal as well as calculating its potential capacity (measured in TEU per year).

Herman Chiu, General Manager, Terminal Development, Group Operations at Hutchison Ports, said the use of simulation technology to terminal design and development during business development or the initial terminal design stages has been adapted to some of the group’s new terminals.

“We build our own simulation models to evaluate different operations modes such as rubber-tyred gantry crane (RTGC) vs rail-mounted gantry crane (RMGC) and automation modes like automated guided vehicle (AGV) vs automated straddle carrier (Auto-SC). These models are also used for terminal layout planning for civil engineering design and capacity planning,” he added.

Equipment sizing and requirement for investment estimation and phased procurement are also simulated.

The next step is to organise the layout of the terminal and determine the type and quantity of equipment required for transportation and stacking for the first test of rough strategies for deployment and allocation. As more detailed information and data becomes available, the more elaborate the results will be including cost and carbon footprint-evaluations.

“The importance of IT systems will increase over the next few years, quality management and assurance systems will also become more important. New technology for automated testing and fine-tuning of the parameter settings for the control systems will be necessary. Particularly, emulation technology supports these tasks by providing virtual terminals. These are simulation models of all terminal processes, which may be directly connected to the terminal operating system (TOS). They may be used as testbeds for the control system of the terminal,” said Schuett.

Tasks during developing, start-up and operating terminals

Source: akquinet AG port consulting GmbH

The main benefit in planning of ‘greenfield’ terminals or the extension of a ‘brownfield’ terminal using simulation applications is to find the optimal layout, including the size and width of stacks as well as the traffic network flow for a planned terminal.

Simulation technology also allows the planner to run sensitivity analysis to explore what happens if some planning assumptions do not turn out as originally assumed and to provide a realistic cost benefit analysis as the simulation-based results are much more reliable compared to static calculations only.

Using virtual terminals allows the terminal operator to test the functionality of the control software, as well as the efficiency of the parameter settings within the control system. Furthermore, the operation staff at the terminal may be trained using this technology – similar to a pilot training in flight simulators.

The last step is using the simulation model of the terminal, also called the ‘digital twin’, to continuously provide with data in parallel to the real live operations with an accurate-to-the-second state of the live terminal. This way the simulation will be able to forecast the operation of the next minutes, hours or shifts and may detect bottlenecks in advance. The operation staff will be enabled to act proactively instead of reacting on challenges.

Nowadays, holistic simulation and emulation products are available in the market, that may be directly used by terminal planners and operators. Typically, first terminal models are created by the specialists, while they may be maintained and configured by the end-user.

Chiu added that simulation models also enable senior or project managers to assess and visualise the outcome of a major investment before making decision and understand where and why terminal bottlenecks occur and if the proposed changes to either the layout, system or equipment would bring in expected improvements.

“The technology can also perform ‘what-if’ analysis and generate quantified advantages or disadvantages for change justification on yard strategy, berth priority and intra-port transfer arrangements,” said Chiu.

Besides the benefits mentioned earlier, specified simulation models may also be used to evaluate the implementation of sequenced expansion phases of an existing terminal. Thus, questions may be answered like:

According to Chiu, “The application for future expansion is the same as planning for a new terminal, except that we can obtain relevant input data from the existing facilities which otherwise are not available for a new site.”

CASE STUDIES

Hutchison Ports BEST

Computer simulation model was built to:

Hutchison Ports Thailand (Terminal D)

Besides the typical KPI of container terminal operations (e.g. moves per hour or boxes handled per hour), simulation technology developer deployed an evaluation approach coming from other industries including automotive and chemicals to the container terminal industry.

The overall equipment effectiveness combines information about the productivity, the utilisation of the equipment and the quality of the process within each single defined KPI.

Therefore, the operation staff can detect potential bottlenecks or inadequate utilisation in one view on the dashboard and may go in deeper in the hierarchical structure of the evaluation results to understand the reasons.

This approach may also be applied to the real operation to show the effectiveness of the current operation in real-time manner.